There are many plastic recycling plants nowadays, but you will know why waste pyrolysis plant is the best. There are various things that most people do not know about this particular company.

First of all, the waste pyrolysis plant uses environmental friendly machines to turn mixed waste plastics into synthetic liquid fuels. Looking at the activity that the company does, it may look very unfriendly to the environment, but this is not the case. The word pyrolysis’ comes from two words pyro’ and lysis’ which means heat and breakdown respectively. This means that pyrolysis is a chemical reaction which involves a molecular breakdown of larger molecules into smaller molecules. This process is done in the presence of heat. More information can be found: https://bestonasia.com/pyrolysis-plant/.

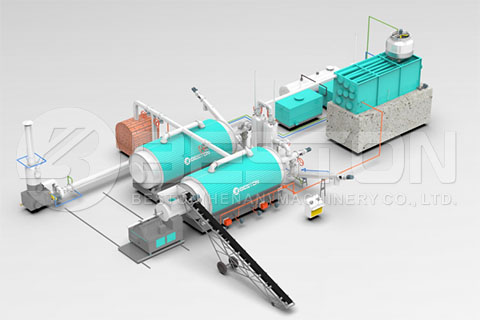

Pyrolysis Plant to South Africa

Therefore, the plant uses the most modern machines to convert waste plastic into industrial fuels which include carbon black, pyrolysis oil, and even hydrocarbon gas.

How Does the Waste Recycling Plant work?

The company uses wastes like tires, rubber, plastic, oil sludge, medical waste, and the plastic. The process involves subjecting the plastic waste to a high temperature of between 400 and 450 degrees Celsius. In the process, there is no oxygen used. The reason for this is to prevent plastic from burning.

In the process of a high quality plastic recycling machine for sale, the plastic is broken down into smaller molecules which include the particles of pyrolysis oil, gas and carbon black. The same method is also used to recycle even the waste tires. You can find more models for sale here: https://bestonasia.com/tire-recycling-machine-for-sale/.

Design of Tyre Recycling Plant

Advantages of waste plastic recycling machinery

Various advantages have made the recycling waste pyrolysis machine to be the best. The devices utilized in the recycling process are very environmentally friendly. It can also be used to recycle other solid waste like waste tyres. For example, the waste tyre to oil machine has a zero emission. For this reason, gases that are released from this device can always be discharged to the air directly since they are pollution free.

Another advantage of the recycling machines used in the plastic recycling pyrolysis is that they have the highest efficiency ever. The new oil type condensers used here ensures that there is an improvement in the yield oil efficiency.

After the process has been completed, the plant comes up with the following end products.

Fuel Oil

The fuel oil is between 45 and 52 percent. This fuel oil can be applied in power plant factory, ceramic factory, aluminum factory, glass factory, painting factory, central heating factory and boiler factory.

Carbon Black

The percentage found after the recycling is 30 to 35 percent of carbon black. This product can be used in the electric cable jacketing, doormat and hose mat, conveyor ban, rubber addictive, automatic spare parts, heat isolation and much more.

It is, therefore, critical to do the recycling because the presence of plastics in the environment may just be hazardous. Plastic waste and tires are some of the wastes that are very dangerous in the environment and therefore recycling is a must. At the same time, the recycling plant needs to be environmental friendly. The machines at the plastic recycling pyrolysis plant are the only ones that handle this process efficiently.

Beston Group is the professional waste recycling pyrolysis plants manufacturer in China. Welcome to visit our company. Or click the website here for a free quote: https://bestonasia.com/.