When you work in construction, you are going to need to use an electric rebar cutter at some point. This invaluable piece of cutting equipment is light and and portable and will cut rebar on the spot. There are also stationary rebar cutting machines you can install in the warehouse and use to process large quantities of rebar. Read on to learn more about the electric rebar cutter and how to choose the right one to buy.

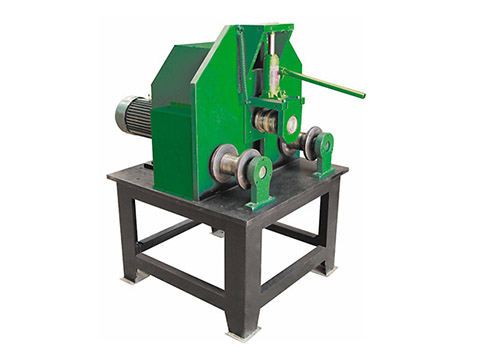

There are two types of rebar cutter you can choose from. You can choose to buy the portable version or the stationary version. Each type of rebar cutter has its own strengths and weaknesses. The portable rebar cutter is the cutter you want to take out on the job. It is easy to carry and very portable.

The portable cutter allows you to make corrections and cut rebar as you are working. You save time and money on labor when you have portable rebar cutters available on the work site. These cutters will cut rebar accurately and they are not noisy so they won’t pose a distraction as you work. They are easy to adjust and easy to use so you won’t have to invest much time in training your workers how to use them.

You want to look for a portable rebar cutter that offers stable performance and can cut well. The cutting ability of the rebar cutter is crucial because it needs to be fast enough to make the cuts you need to make. It is also crucial that the rebar cutter be as accurate as possible. You don’t want workers making cuts that are wrong. This costs you money and leads to more time spent on the job.

You also want a rebar cutter that is easy to adjust and has a sturdy blade. Durable blades mean less time that goes between changing them. When it comes time to replace the blade, you want to make sure that the blade is easy to change. Make sure the rebar cutter you choose is made with parts that are high quality. You want the machine to be as light as possible so it isn’t too hard for the workers to carry around with them.

Electric rebar cutters make working faster and they make working easier. The cutters are reliable and they are something that every employee needs to have available. Workers need to have the ability to cut rebar on the spot. There are always adjustments that need to be made as they are working and the rebar cutter will make things easier and more effective. If you want to improve the job performance and effectiveness of your employees, then you need to use a rebar cutter from reputable supplier.

When you are ready to order your rebar cutters http://ellsenrebarprocessingmachine.com/electric-rebar-cutter/, make sure you are familiar with the cutting capacity of each type of cutter and make sure that you look for the cutter that meets the needs of all your workers.