If you know anything about pyrolysis plants, you will know that there are two main types: continuous processing plants and batch processing plants. Both these configurations make financial sense in particular situations. In this blog post, we will explore the topic of continuous processing pyrolysis plant and its advantages., In the end, we will also cover what you should do to get the best value for your money when buying this type of continuous tyre pyrolysis plant.

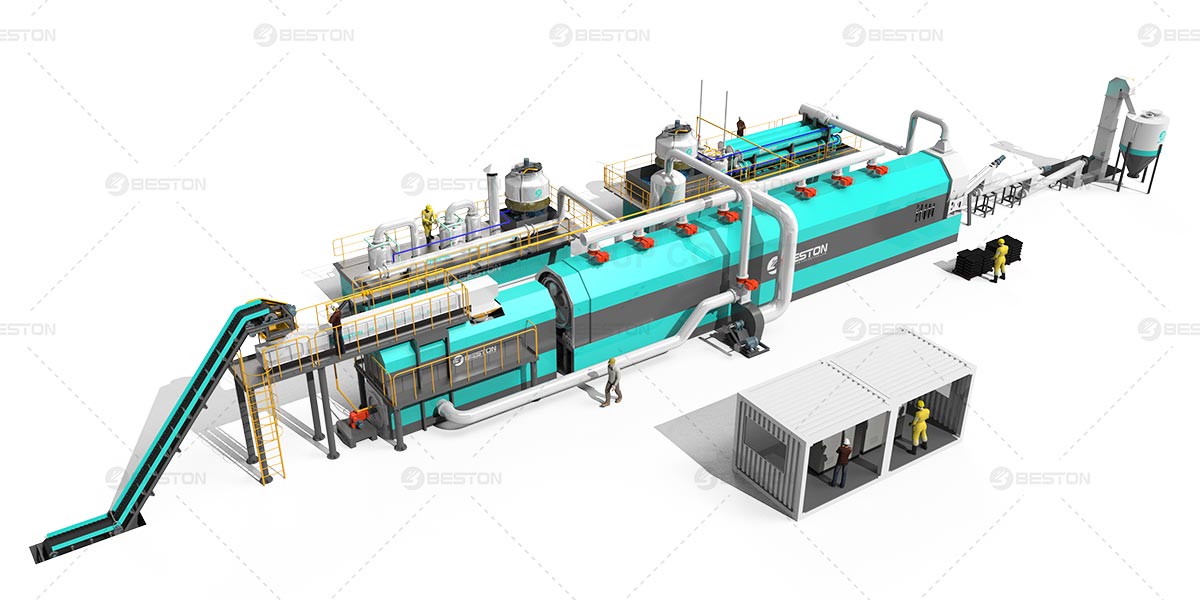

3D Layout of Continuous Pyrolysis Plant

Extremely High Processing Capacity

The major difference between a batch processing plant and a continuous processing plant is that a continuous plant can operate 24 x 7 for several weeks at a stretch due to its relatively simple design. That is not the case with a batch processing plant as it processes in batches and you can make changes to the setting between batches. Since a continuous plant operates 24 x 7, it offers a huge processing capacity which cannot be matched by a batch processing plant.

If you have a huge amount of material to process, a continuous tyre pyrolysis machine makes much more financial sense. Since these plants have a higher processing capacity, they are also much more efficient as no changes to the specifications are required to be made.

Complete Automation

Another reason for the high processing capacity of a continuous type plant is complete automation. Automation not only helps in cutting down on the number of operators required for operating the plant but also ensures fewer human errors which translate into better efficiency and better yield. Fully automated plants are also easier to operate as everything is done automatically and you don’t need to fiddle with the settings too much.

Better Yield as Compared to a Batch Plant

Continuous plants offer much better yield as compared to batch plants due to the nature of processing itself and higher efficiency. The key is a simpler design and continuous processing. On the other hand, batch plants are much more suited to processing different types of materials and are much more complicated in design as compared to continuous waste pyrolysis machine.

Installation of Continuous Tyre Pyrolysis Plant

There Are Several Options

There are hundreds of manufacturers of these plants which means you have a ton of options in terms of processing capacity, design, automation level and other important parameters. High competition also means that the prices are always competitive.

Where to Buy the Right Plant?

When it comes to choosing a manufacturer, your focus should be on the reputation of the manufacturer, after sales service, long-term performance of the plant, fuel efficiency and other important parameters. First, you need to choose the right processing capacity. Make sure you buy enough processing capacity to satisfy your requirements.

Pay equal attention to the manufacturer’s reputation. Choose a company that is known for high quality of their products. After sales service is also important as you will need to replace some parts, every now and then. While every buyer pays attention to the price, don’t hesitate to pay extra for a better performing brand.

Final Thoughts

Overall, a continuous pyrolysis plant of Beston Group offers a number of advantages over its batch processing counterpart. It makes perfect sense in situations where a large amount of the same material needs to be processed as these plants have a huge processing capacity and are more efficient as compared to their batch processing counterparts. Always focus on the long-term performance instead of price when buying this plant to set up a solid foundation for your business.