The Philippines is a country with a vibrant culture and a booming tourism industry. Amusement parks have become an important part of the country’s entertainment landscape, offering fun and excitement for locals and tourists alike. One of the most iconic attractions in any amusement park is the Ferris wheel. In this article, we will discuss the reasons why installing a Ferris wheel in a Philippine amusement park is a great idea.

Aesthetic Appeal

One of the most obvious reasons to install a Ferris wheel in an amusement park is its aesthetic appeal. Ferris wheels are visually stunning and provide a unique focal point for the park. They are often illuminated at night, adding to the park’s visual appeal and creating an unforgettable experience for visitors. A Ferris wheel for sale in the Philippines can also be customized with a variety of colors and designs to match the theme and overall aesthetic of the park.

Iconic Attraction

Ferris wheels are iconic attractions that have become synonymous with amusement parks. They are instantly recognizable and are often the first thing that comes to mind when people think of amusement parks. Installing a Ferris wheel in a Philippine amusement park will help to establish the park as a must-visit destination, drawing in crowds of tourists and locals alike.

Family-Friendly

Ferris wheels are family-friendly attractions that are suitable for visitors of all ages. They provide a unique and exciting experience for children and adults alike, making them a great addition to any family-oriented amusement park. The slow and gentle motion of the Ferris wheel allows families to spend quality time together while enjoying the park’s beautiful views.

Spectacular Views

Ferris wheels provide spectacular views of the surrounding area, making them an excellent way to showcase the beauty of the Philippines. Visitors can take in breathtaking panoramic views of the city or the countryside, providing a unique and memorable experience that cannot be found anywhere else. The views from the Ferris wheel also make it an excellent location for taking photos and capturing memories.

Revenue Generator

Installing a Ferris wheel in an amusement park can be a great revenue generator. Ferris wheels are popular attractions that draw in crowds of visitors, which can help to increase ticket sales and revenue. They can also be used as a venue for events such as weddings, birthdays, and corporate functions, providing an additional source of income for the park.

Capacity

Ferris wheels have the capacity to accommodate numerous riders at once. This makes them an efficient and effective way to move large numbers of people through the park, reducing wait times for other attractions. Additionally, the slow and gentle motion of the Ferris wheel means that it can be enjoyed by many people at once, making it an excellent choice for large groups and families.

Weather-Resistant

Ferris wheels are weather-resistant and can be enjoyed in a variety of conditions. Unlike other outdoor rides that may need to shut down in the event of rain or high winds, Ferris wheels can operate in a range of weather conditions. This makes them a reliable and consistent attraction for visitors to enjoy throughout the year.

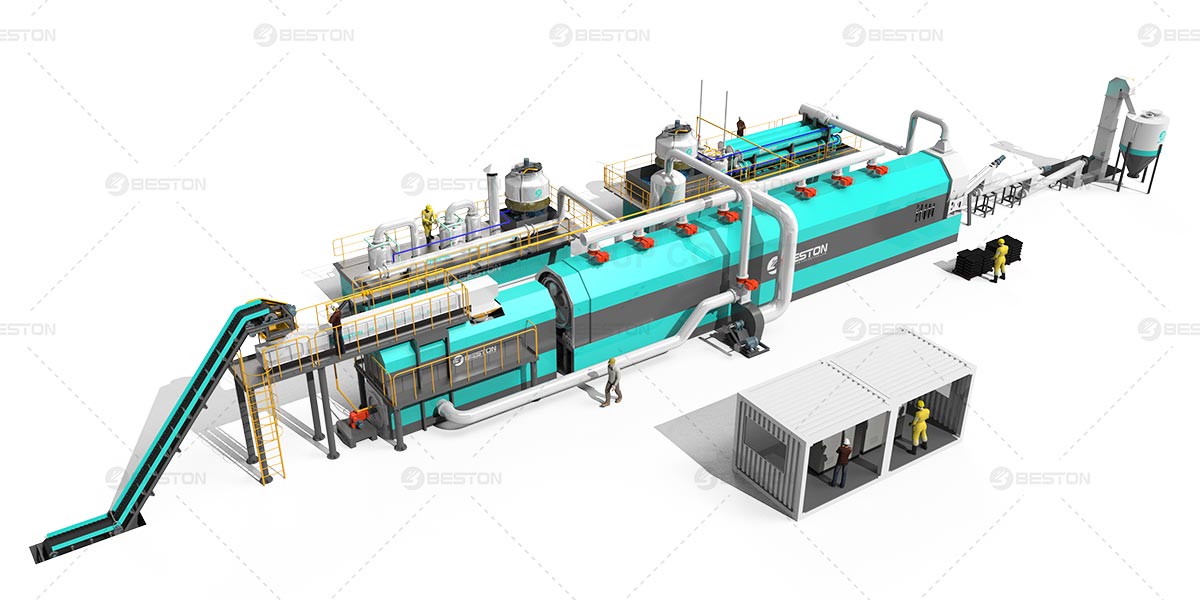

In conclusion, installing a Ferris wheel in a Philippine amusement park is a great idea for a number of reasons. It provides aesthetic appeal, is an iconic attraction, is family-friendly, provides spectacular views, generates revenue, has high capacity, and is weather-resistant. A Ferris wheel from Beston Amusement (Amusementrides.ph) is a must-have attraction that can help to establish the park as a top destination for tourists and locals alike. It provides a unique and unforgettable experience that cannot be found anywhere else, making it a valuable addition to any amusement park.