We all are using plastics on a daily basis. But have you ever thought that you can use the waste plastics in the best possible manner? Yes, it is possible. You are converting plastic to oil through a new technology. The plastic to fuel conversion machine can make it happen within a couple of hours. The plastic to fuel conversion machine that is popularly known as the pyrolysis plant that uses top-notch technologies to convert the waste plastics into the usable fuels along with the hydrogen gas and the carbon black. The process will be safe, effective, and environment-friendly.

What will be the process of plastic to fuel conversion machine?

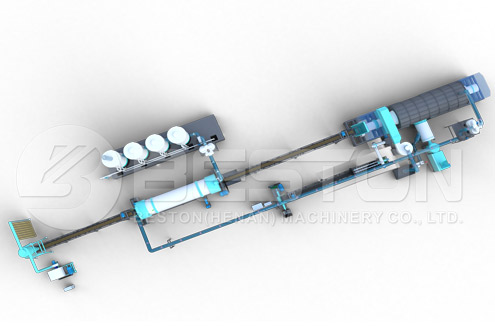

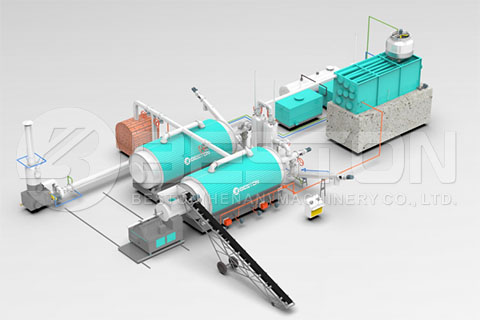

The process will be simple and less time consuming. It will go through a systematic process to achieve the end result. First, it will shred the plastics and will keep them in the high temperature around 400-450 degree Celsius in an oxygen-free chamber. These waste plastics will be melted and finally vaporized into the gas. The gasses will be cooled down and condensed to get the fuel oil, carbon black, and the combustible gas. The plastic to fuel conversion plants produce clean and purified fuel oil that can be used without any further cleaning.

The fuel from waste plastic is widely used in different industries for different purposes. Some of the usages are the followings.

* These are used in the heavy generators to produce electricity in different types of the industries.

* These oils can also be used as the heating material to convert the waste plastics into the fuel oil.

* These can be used in the grease refining factories for the processing.

* These fuels can be used in the electrical energy, ceramic, glass, and steel making companies help the production process.

What are the benefits?

Plastic to fuel conversion machine has many economic and environmental benefits. First of all, it reduces the amount of the waste plastics that can pollute the environment significantly. Secondly, it is economically viable and it promotes the reuse of the waste material and turn plastic into fuel. It also reduces the emission of the greenhouse gasses.

Plastic to fuel conversion machine can convert all the waste plastics into the fuel oil. The process will be simple and useful. Please visit our website for more info about the machine: https://bestonpyrolysisplant.com/waste-plastic-to-fuel-conversion-plant/.Through this process, you can use different types of the plastics such as the lids, bottles, bags, containers, wraps, and caps for the fuel oil conversion. These plastics can cause environment pollution and you cannot destroy them completely without causing harm to the environment. Hence, this is the best way to use the waste plastics.

Another important thing that you are going to want to factor into your buying decision is the price. While it would be nice to be able to get the lowest possible price along with the best possible quality, this is often not going to be the case. If you dive around for the lowest price, you are typically going to be greeted with a low quality machine. Instead of looking for the lowest price, you are going to want to search around for the best bang for your buck. Meaning, you will want to try to find a manufacturer that offers an incredible amount of experience, after market service, and a great reputation for a good and fair price. Reasonable price, best quality and perfect after-sales service are our advantages. By finding the best value, you should be able to avoid purchasing a machine that is priced low because it is low quality. Meanwhile, Our

Another important thing that you are going to want to factor into your buying decision is the price. While it would be nice to be able to get the lowest possible price along with the best possible quality, this is often not going to be the case. If you dive around for the lowest price, you are typically going to be greeted with a low quality machine. Instead of looking for the lowest price, you are going to want to search around for the best bang for your buck. Meaning, you will want to try to find a manufacturer that offers an incredible amount of experience, after market service, and a great reputation for a good and fair price. Reasonable price, best quality and perfect after-sales service are our advantages. By finding the best value, you should be able to avoid purchasing a machine that is priced low because it is low quality. Meanwhile, Our