There exists one ride that there are actually it amusement parks which may have not been intentionally made for the only intent behind amusement. It really is referred to as the human gyroscope ride. Although they go by a lot of different names such as the aerotrim, it is actually something which was adopted by the United States space program as a way to prepare people for space travel, in the absence of gravity. Today, these are still available at many amusement parks and are enjoyed by the ones that like to spin around in circles extremely fast. You can easily have multiple people on one ride, which makes it fun for the family, and this is an overview of how they work.

A Persons Gyroscope Ride

These rides could be either small, containing just one single person who is actually seated in the center. It can spin forwards, backwards, and at many angles and directions, disrupting your perception around the globe surrounding you. Some of them can easily operate under their very own power, whereas other people are human powered because they were originally designed. Typically, they may not spin so quickly concerning get people sick, but they can easily do this as astronauts discovered at the Kennedy Space Center throughout their training.

How Exactly Does It Work?

There are three concentric rings where a person resides in between. On a regular gyroscope, for example, there is the center rotor that is horizontal, the spin axis that is perpendicular to the rotor, and also the gimble that is outside each of those. Addititionally there is the gyroscope frame, residing on the exterior from the ride, and each of this will spin on the 3 axes, creating the incredible rotations that could occur.

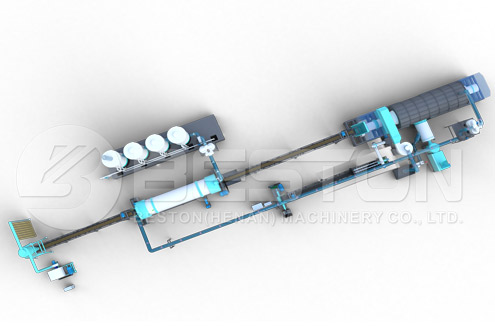

Beston 6 cabins orbitron ride for sale

Working You Buy Them?

If you are searching for one human gyroscope for sale either because patrons have asked about the subject, or you have someone else you are aware of in the marketplace that is certainly actually attracting a lot more people by introducing one on the market amusement park or carnival, you must certainly think about using one in your workplace. Although these will not generate a similar excitement as a fast moving roller coaster, they can be definitely going to maneuver the occupant, or multiple occupants, quickly in circles, offering them a ride that they may remember. You can purchase these from either businesses that are upgrading, or perhaps used ones which are simply purchased at an amusement park wholesale store. If you purchase them overseas, you may typically have the latest designs, and get them for discounted prices, allowing you to come with an absolutely new orbitron ride for sale beyond the competitors.

It doesn’t take much to have the moving, and should you use the spaceball ride that is made for more than one person, they often times are self-propelled. In either case, these are going to be a thrilling addition to your theme park to be able to advertise to generate additional visitors that have always wanted to ride one, but could never choose a carnival that had one ready and available. For other kiddie ride for sale, you could contact Beston Amusement Equipment Co., Ltd.